Dark Factories: The Future of Work

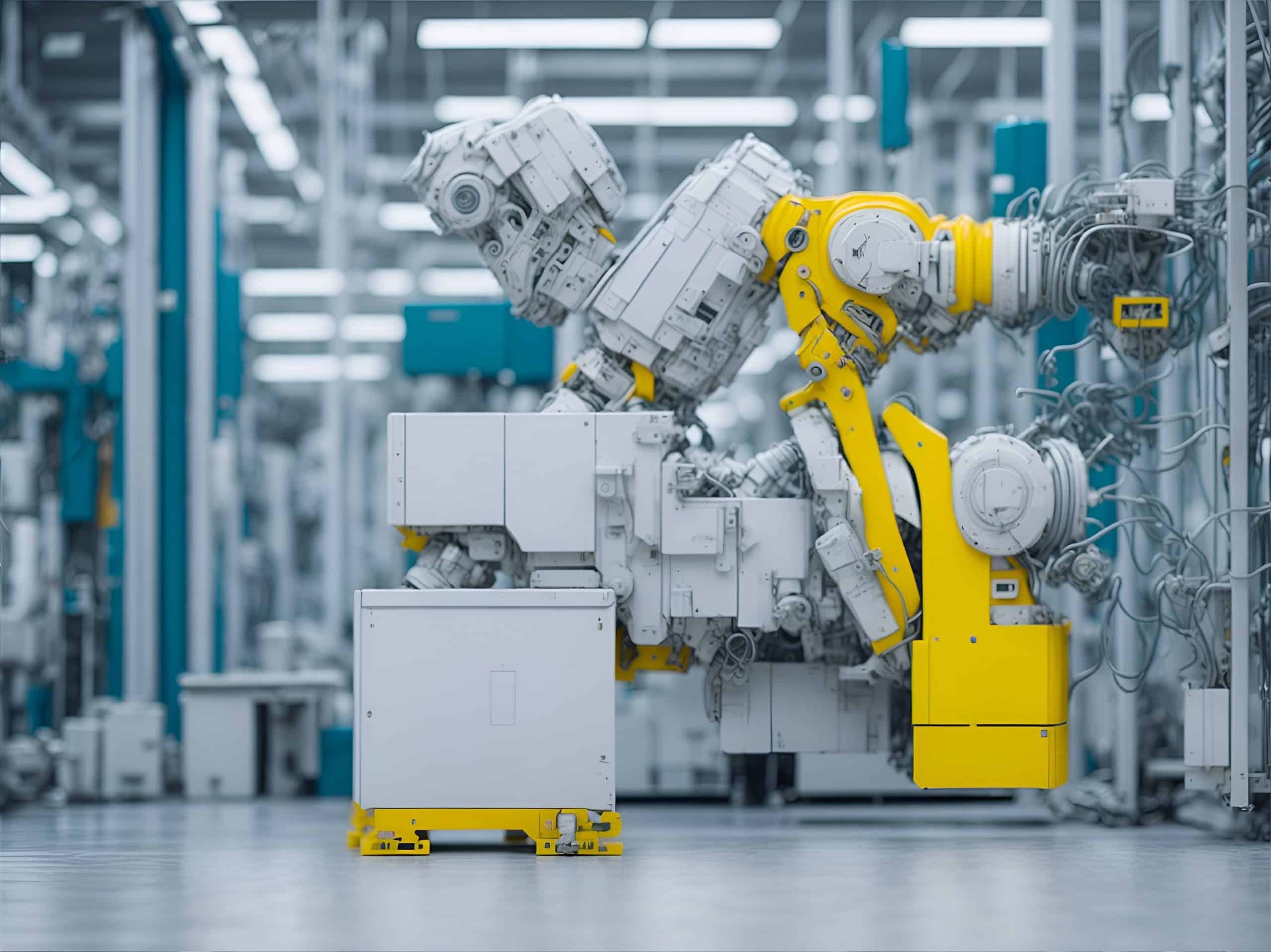

Rise of Fully Automated ‘Dark Factories’: The Future of Manufacturing

Introduction: What Are Dark Factories?

Dark factories, also known as “lights-out manufacturing,” are fully automated production facilities that operate without human workers. These factories leverage AI, robotics, and IoT to produce goods with minimal human intervention, reducing costs and increasing efficiency.

In China, Xiaomi operates a dark factory capable of producing one smartphone per second, revolutionizing traditional manufacturing processes. As more companies embrace automation, the question arises: Are dark factories the future of global manufacturing, or do they pose risks to employment?

???? Related Post: Download Unknown Partners Nigerian Movie 2025

How Dark Factories Work

Dark factories rely on the latest Industry 4.0 technologies, including:

- Robotics & AI – Machines handle assembly, quality control, and packaging.

- IoT & Smart Sensors – These devices monitor production in real-time.

- Machine Learning Algorithms – AI optimizes workflow and detects defects.

- Cloud-Based Management Systems – Allows remote monitoring and predictive maintenance.

???? Example: Xiaomi’s Smart Factory in Changping, China, is 100% automated, producing phones faster than any human-run assembly line.

???? External Source: How China’s Dark Factories Are Transforming Manufacturing.

Key Technologies Powering Fully Automated Factories

Dark factories utilize cutting-edge automation technology, including:

- AI-Driven Robotics – Machines perform tasks with precision.

- Smart IoT Sensors – Real-time monitoring and predictive maintenance.

- Cloud-Based Manufacturing Systems – Remote operation and efficiency tracking.

Benefits of Dark Factories

✅ 1. 24/7 Productivity

Unlike traditional factories, dark factories never stop. Machines work around the clock without breaks, improving productivity.

✅ 2. Cost Reduction

- Eliminates labor costs (no salaries, benefits, or HR expenses).

- Reduces utility costs (less need for lighting, heating, or air conditioning).

✅ 3. Precision & Quality Control

AI-driven defect detection improves product quality. Error rates are reduced because machines follow strict programming.

✅ 4. Increased Safety

With no human workers, risks like accidents, injuries, and contamination are minimized.

✅ 5. Environmental Sustainability

Dark factories use optimized energy consumption, minimal waste, and recyclable materials, making them more eco-friendly.

???? External Source: AI & Robotics: The Future of Manufacturing

❌ Downsides & Challenges of Dark Factories

1. Job Loss & Rising Unemployment in the Age of Automation

The biggest downside of dark factories is mass job displacement. As robots and AI take over manufacturing roles, millions of factory workers could face unemployment, worsening income inequality.

???? Example: Foxconn, Apple’s supplier, replaced 60,000 human workers with robots in a single year, drastically reducing labor costs but eliminating thousands of jobs.

2. High Initial Investment & Cost Barriers

Setting up a fully automated lights-out factory requires millions of dollars in investment.

- Small manufacturers struggle to afford the transition.

- High-tech robotics, AI systems, and IoT integration demand continuous upgrades, increasing operational expenses.

???? Example: Tesla’s Gigafactories invest billions in automation, making it nearly impossible for smaller companies to compete.

3. Over-Reliance on AI & Risk of System Failures

Dark factories depend entirely on AI-driven robotics. A software glitch, cyberattack, or hardware failure could bring an entire factory to a standstill, leading to massive financial losses.

???? Example: In 2020, a major Tesla factory automation failure forced the company to temporarily shift back to human workers to keep production running.

4. Ethical Concerns: Should Profits Come Before People?

Dark factories raise serious ethical questions:

- Should corporations prioritize cost-cutting automation over human employment?

- Should governments regulate AI-driven job displacement?

???? Potential Solution: Some governments are proposing automation taxes or mandatory reskilling programs to balance the impact of robot-driven unemployment.

Final Thoughts on the Challenges

While fully automated factories offer efficiency and cost savings, they also present economic, ethical, and financial risks. Finding the right balance between automation and human labor will be critical for a sustainable future in manufacturing.

???? External Source: How Automation is Affecting Global Jobs

Countries Leading in Dark Factories Technology

| Country | Notable Dark Factories | Industry Focus |

|---|---|---|

| China | Xiaomi Smart Factory | Electronics |

| Japan | FANUC Robotics Plant | Robotics |

| USA | Tesla Gigafactories | EV Production |

| Germany | Siemens Industry 4.0 | Engineering |

China and Japan are leading the automation race, while the US and Germany are implementing AI-driven manufacturing at scale.

???? External Source: Dark Factories and the Future of Industry 4.0

The Future of Fully Automated Factories

???? Global Impact on Industries

Dark factories will revolutionize industries beyond electronics & automotive, including:

- Pharmaceuticals – AI-driven drug production.

- Textile & Fashion – Robotic garment manufacturing.

- Food Processing – Fully automated food production lines.

???? External Source: How AI Is Shaping the Future of Food & Pharma

???????? Will Humans Still Be Needed?

- Instead of manual labor, humans will monitor and maintain AI-driven systems.

- New jobs in robotics maintenance, AI programming, and cybersecurity will emerge.

The Impact of Fully Automated Factories

Economic Disruption & Workforce Transition

The widespread adoption of dark factories will reshape global economies, leading to a decline in traditional manufacturing jobs. While companies benefit from increased efficiency and reduced costs, millions of factory workers may struggle to find employment. Governments worldwide must invest in reskilling and upskilling programs to help displaced workers transition into AI management, robotics maintenance, and data analysis roles. Without proper policies, the economic divide between tech-driven nations and labor-dependent economies could widen, increasing inequality and social unrest.

Shift in Global Manufacturing Dominance

As automation reduces labor costs, companies no longer need to outsource production to low-wage countries. This could lead to a reshoring trend, where manufacturing moves back to highly developed economies like the US, Germany, and Japan. However, nations that rely heavily on manufacturing exports, such as India, China, and Mexico, might face economic slowdowns unless they invest in AI-driven industries. The future of global trade will likely favor countries with advanced automation infrastructure, leading to new power dynamics in international markets.

Conclusion: Is This the End of Human Labor?

Dark factories represent the next evolution in industrial manufacturing, offering speed, efficiency, and lower costs. However, they also raise ethical and economic concerns regarding mass unemployment.

As governments and businesses adapt, a balance between automation and human employment must be maintained. While machines take over repetitive tasks, humans must upskill for AI-driven roles in the future of work.

???? What do you think? Are dark factories the future, or do they pose a serious threat to jobs? Let us know in the comments below!

1 thoughts on “Dark Factories: The Future of Work”